- the ability of a structure to support a designed load without bending, collapsing, or breaking

Structural failure

- created when the material is stressed to its strength limit, thus causing fracture or excessive deformations.

Common types of failure:

1. Fracture:

Brittle vs. Ductile

(a) Very ductile, soft metals (e.g. Pb, Au) at room temperature, other metals, polymers, glasses at high temperature.

(b) Moderately ductile fracture, typical metals

(c) Brittle fracture, cold metals and ceramics.

*brittle fracture → rapid run of cracks through stressed material.

*very little plastic deformation

*No warning → worst type of fracture

*Amorphous microstructures (glass) produce shiny brittle fracture surfaces

In crystalline materials:

transgranular fracture - travels through the grain of the material

intergranular fracture - crack traveling along the grain boundaries

2. deformation

- object returns to its original shape

- Not permanent

Plastic Deformation:

Plastic Deformation:

- object becomes permanently deformed

3. Fatigue

The weakening of a material caused by repeatedly applied loads.

Fatigue life depends on:

- Temperature

- surface finish

- atomic microstructure

Things to avoid:

Sharp corners & bends - make everything smooth!

Example: 90° corner:

Use the probe to point out where the max stress is:

Same loading force, comparison of max stress with and without fillet:

1.411 vs. 0.58 → stress along 90° corner is ~ 2.5 times larger than the stress along the fillet.

Find where stress is concentrating on your bridge for various loading conditions, then redesign joints to more homogeneously distribute the load.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Fatigue rules of thumb:

Design Criteria:

Localized failure should not cause immediate or even progressive collapse of the entire structure.

Test for "critical" spots on your bridge.

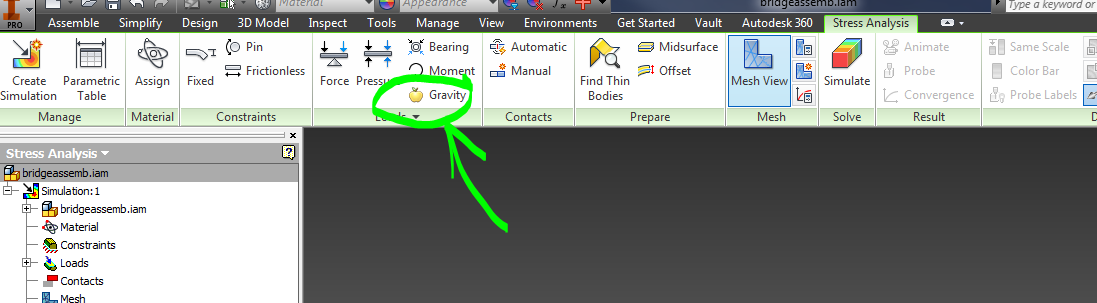

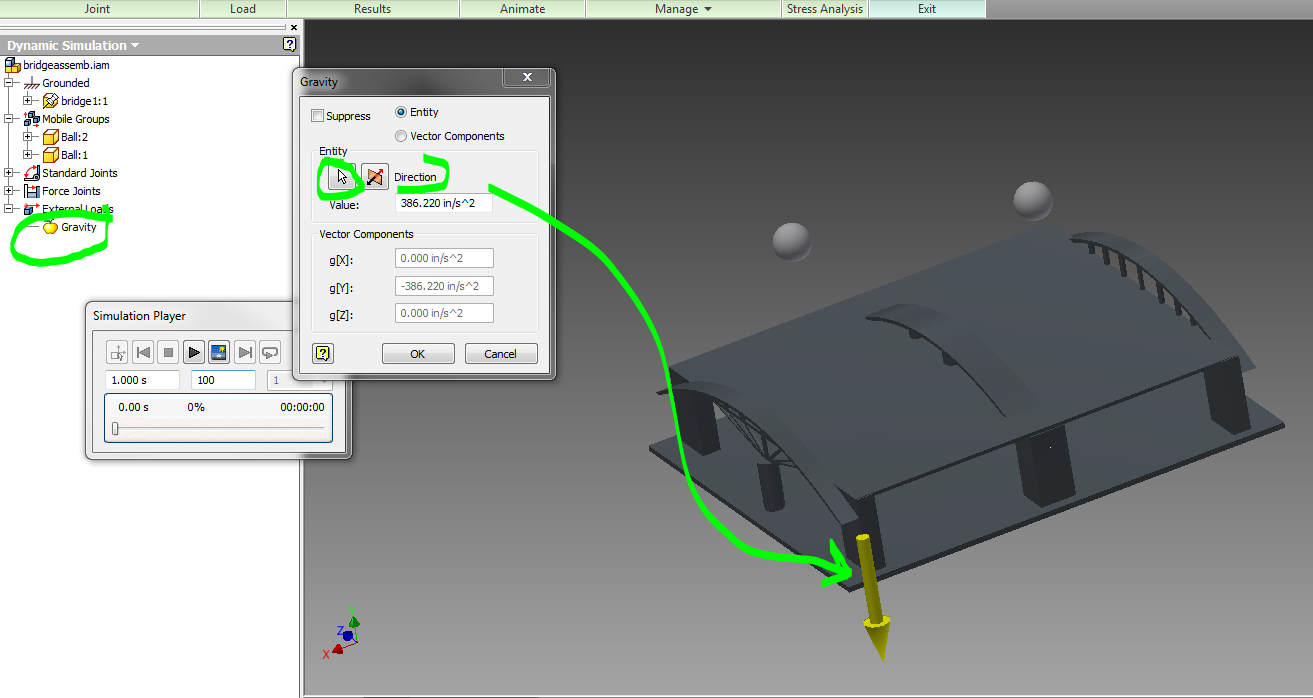

Run a FEA sim where you apply a forces to critical spots (at supports and joints).

Modal Analysis

Earthquake? Wind? Vibrating machinery? Vibrating cars & trucks?

Modal Analysis solves for natural vibrational tendencies of a structure in the form of mode shapes and frequencies.

Try just applying one fixed constraint, and then run the simulation without any other applied forces.

Use the animate tool to watch it vibrate!

Display the position of your center of gravity, and notice the influence of the center of gravity on the vibrational patterns in your bridge:

View → Center of Gravity

Notice how everything vibrates around the center of gravity.

Think about the main causes of bridge failure, and then decide how to modify your bridge to avoid these types of failures.

Find the mass, volume, center of mass etc. of your part:

What on your bridge is over-designed? Where can you remove a little bit of material to reduce costs?